WE PRINT BONE™

The bone substitutes are not cleared by the regulatory authorities and therefore not approved for sale.

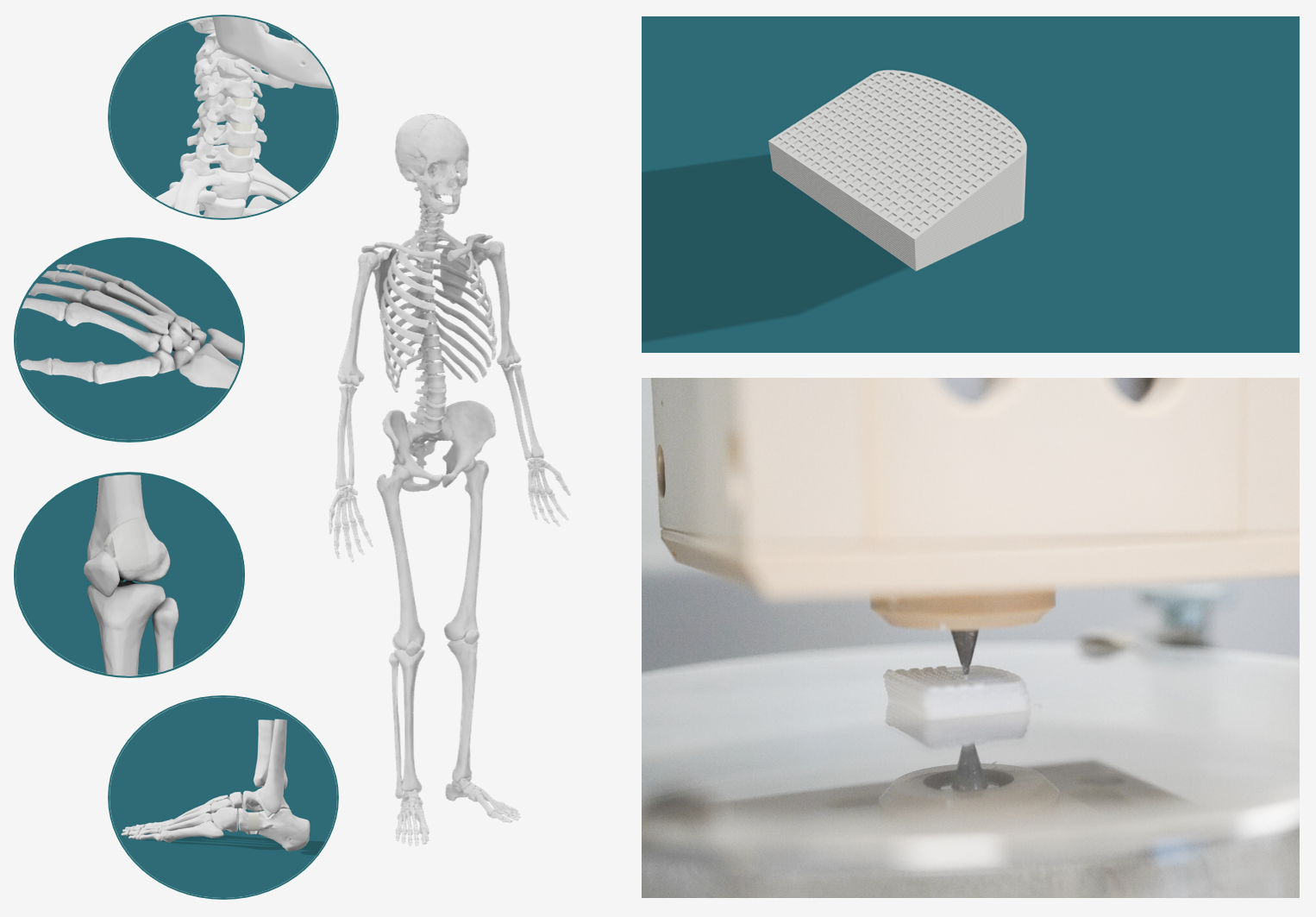

Bio-integrative and structural orthopedic bone substitutes

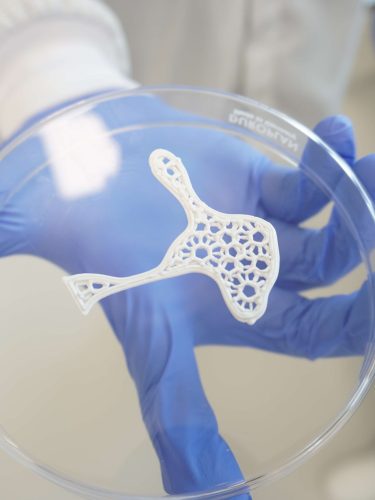

Ossiform® develops bioactive bone substitutes that provide structure while facilitating the natural forming of new bone.

The bone substitutes are made from 3D printed ß-tricalcium phosphate – a fully resorbable material with tailored properties, optimized for bone regeneration and indication-specific biomechanical thresholds.

In short: We Print Bone™.

Our aim is to allow surgeons to reconstruct bone without the complications of foreign body implantation – or the variable quality of allografts.

The Ossiform Bone illustrations shown on this site are intended to demonstrate potential use cases, they are not cleared by the regulatory authorities and are therefore not approved for sale.

The technology has been tested in preclinical studies only. Results from in vitro and in vivo tests may not be predictive of clinical performance.

About Ossiform®

We are continuously working to redefine bone replacements through progressive research and close collaboration with physicians and industry partners. Our patient-centric approach and commitment to innovation, quality, and progress steer our efforts to provide best-in-class implant solutions that facilitate the natural forming of new bone.

That's why, We Print Bone™

The technology has been tested in preclinical studies only. Results from in vitro and in vivo tests may not be predictive of clinical performance.

Technology explained

For researchers

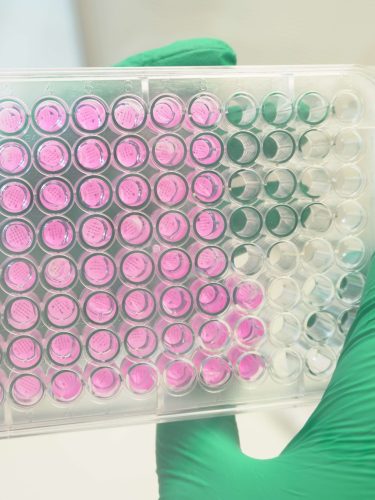

Bone tissue engineering in preclinical research

Ossiform’s expertise in medical 3D printing is further used to provide a research product line of natural bone-like environments wherein disease mechanisms can be studied and new treatments can be tested.

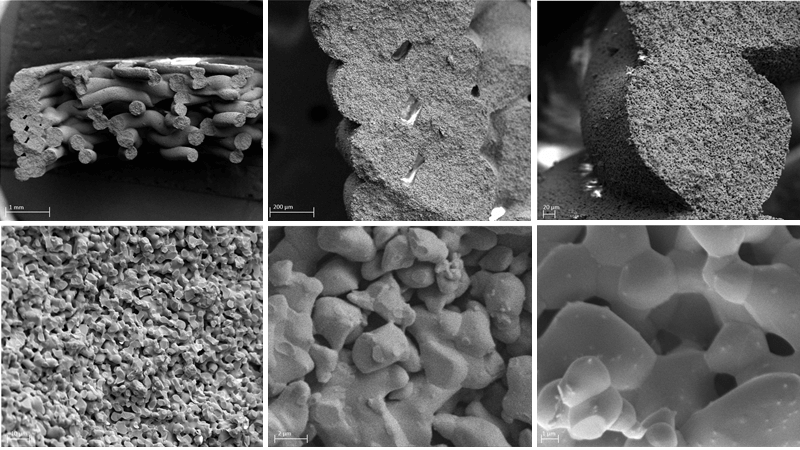

SEM image of P3D Scaffolds. Picture courtesy of Luis Eduardo Carneiro-Campos, PhD.